Hemingway84

2020-12-30 23:02:06

- #1

Foreword:

We are building a city villa with 190 sqm of living space according to KFW 55 standard with a large general contractor from Königslutter in the Berlin metropolitan area. This contractor employs various subcontractors, who in turn work with sub-subcontractors (some of whom also employ sub-subcontractors). So far, numerous construction defects have occurred. Serious construction defects could still be prevented through our intervention (for example, the formwork of the intermediate ceiling, which was several centimeters too low, was literally raised 5 minutes before the concrete was poured). Unfortunately, the site manager is incompetent, thin-skinned, and blind. From day one, there have only been silly remarks and lack of motivation. He has never recognized defects himself to date or has only reluctantly addressed those reported by us, or tried to play them down with standard phrases.

In fact, we are on the construction site as often as possible because, due to the other defects that have occurred so far, we are on constant alert. Our intervention has already improved or, from our point of view, saved many things. We have also engaged a construction supervisor, who has already added value here and there, but whose passion lies more in photographing the construction than in detecting defects. Sometimes a tape measure or a spirit level is enough, at least for us.

Our construction project is rounded off by the fact that my wife was diagnosed with cancer a few months after purchasing the land and signing the construction contract. A miserable stroke of fate with chemotherapy and all related side effects, framed by the external circumstances of the Corona pandemic affecting us all. The loss of earnings is unfavorable but was anticipated sufficiently in the financing—although originally considered as possible parental leave and not long-term illness. Nevertheless, everything is even more exhausting than it probably would have been otherwise.

Main Part:

We are approaching the end of construction, the screed drying will be completed next week (scheduled house handover at the end of January, thus just missing the VAT reduction as well). 90% of the house price has already been paid; only the final invoice, likely arriving in the next few weeks, remains open.

At the end of November, the exterior plaster was applied. At that time and in the days following, the outside temperature did not exceed 5 degrees, with nighttime temperatures occasionally below freezing. According to the plaster manufacturer (Alsecco), the silicate plaster used may only be applied up to 5 degrees Celsius outside temperature and must remain above 5 degrees consistently in the days after. If this is not the case, the plaster cannot properly cure, which can lead to damage regarding strength and durability.

One day before the plaster work began, we submitted an informal notice of concern to the general contractor and the construction coordinator regarding the weather forecast. In response, the subcontractor stated that there was no reason to worry and that he was even offering a one-year extended warranty on his own initiative.

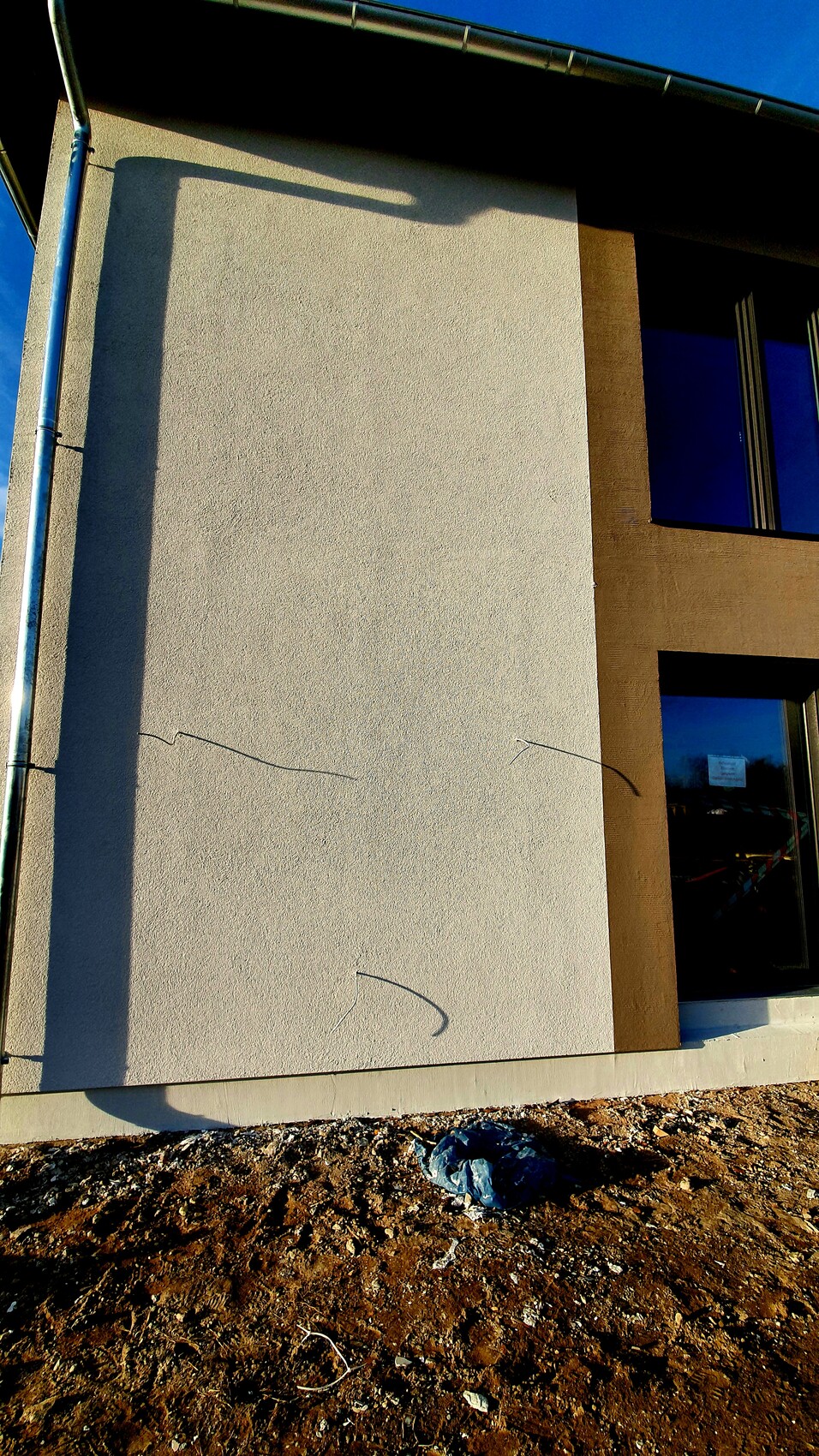

The plastering was carried out, with the result that the exterior plaster was still soft even after a week. In some places, it has "slid down," especially on window sills. See pictures for details.

The subcontractor who applied the exterior plaster also recently installed the window sills—but only after the external thermal insulation composite system (ETICS) and facade reinforcement were applied—and they installed them crooked and uneven. In some cases, the window sills also seem to be too short. On average, they protrude only about 2-3 cm. Some are also uneven, for example, one side 1.5 cm, the other side 3 cm. The underside drip groove is often flush with the facade. Drinking took place during the installation of the window sills, as evidenced by several (approximately middle double-digit) "short drinks" found scattered near the scaffolding. It was also "nice" that our sometimes 3 m long window sills were simply cut with an angle grinder because, as stated, they would not otherwise have fit into the car. It was forgotten that the joint then needed to be sealed.

The window sills also show no visible sealing. According to professional associations, there should be two sealing levels on window sills with ETICS. I see none. I also find it odd that the window sills were cut into the ETICS. The unnecessarily large gaps created there were either not filled at all or only with silicone or similar, which after more than four weeks is still not cured and is soft.

Water continually collects on the edges of the window sills, running down the facade, further soaking the plaster, and in some places freezing or freezing into the plaster. Where could this water be coming from? Inside, the screed drying process is still ongoing with corresponding heat. Could this be an indication of leaks around the windows? The interior moisture is consistently removed using three construction dryers (currently below 40% humidity). The suspicion of a leak around the windows arises because I found significant residual moisture along with slight bulging of the interior plaster at the worst-affected window corner inside. Elsewhere, the interior plaster is superficially dry.

The base of the house was also only half-heartedly delivered by the same subcontractor. A very thinly scratched reinforcement plaster can never be the sealing plaster against moisture as agreed in the construction services description because it is simply too thin and, as the pictures show, always damp (without rain!).

Outlook:

What happens next? The defects have been reported, documented with photos, and recorded. Should one still accept the handover conditionally with such defects, or refuse acceptance altogether? We would like to move in at the end of February, as my wife has her follow-up treatment after chemotherapy starting in March and does not need moving stress afterward, which would negate any recovery. The possible double burden is also not without consequence.

The plaster is visibly ruined and in reality crumbly, patchy, and simply poorly done. In our opinion, it must be completely removed and redone. The window sills must also be taken out and reinstalled, as they are too short and in some cases unnecessarily cut with an angle grinder. Our concern is especially the sealing and possible damage to the ETICS. Who knows what it will be like in a few years.

Next week, at our own expense, we will bring in a publicly appointed expert for the painting trade to clarify the severity of the damage and necessary repairs. From the general contractor and our site manager, based on experience, we expect little to nothing. We want to remain firm and not agree to any repair work or credit notes. For now, we only see the solution as "everything from scratch." That would be really expensive and particularly interesting regarding payment of the final installment.

We have only received a 5% completion bond from the general contractor, which would probably not be sufficient for a complete re-execution of the defect (and according to the contract text, may only be retained after the house handover for serious defects). However, referring to this bond, he has already suggested that under all circumstances he will insist on 100% payment by us upon acceptance, as we have this bond from him as security and it could be increased or extended.

Hints, comments, ideas, suggestions ... all welcome. I just had to "vent." Sometimes you really feel helpless and lost as a building owner.

We are building a city villa with 190 sqm of living space according to KFW 55 standard with a large general contractor from Königslutter in the Berlin metropolitan area. This contractor employs various subcontractors, who in turn work with sub-subcontractors (some of whom also employ sub-subcontractors). So far, numerous construction defects have occurred. Serious construction defects could still be prevented through our intervention (for example, the formwork of the intermediate ceiling, which was several centimeters too low, was literally raised 5 minutes before the concrete was poured). Unfortunately, the site manager is incompetent, thin-skinned, and blind. From day one, there have only been silly remarks and lack of motivation. He has never recognized defects himself to date or has only reluctantly addressed those reported by us, or tried to play them down with standard phrases.

In fact, we are on the construction site as often as possible because, due to the other defects that have occurred so far, we are on constant alert. Our intervention has already improved or, from our point of view, saved many things. We have also engaged a construction supervisor, who has already added value here and there, but whose passion lies more in photographing the construction than in detecting defects. Sometimes a tape measure or a spirit level is enough, at least for us.

Our construction project is rounded off by the fact that my wife was diagnosed with cancer a few months after purchasing the land and signing the construction contract. A miserable stroke of fate with chemotherapy and all related side effects, framed by the external circumstances of the Corona pandemic affecting us all. The loss of earnings is unfavorable but was anticipated sufficiently in the financing—although originally considered as possible parental leave and not long-term illness. Nevertheless, everything is even more exhausting than it probably would have been otherwise.

Main Part:

We are approaching the end of construction, the screed drying will be completed next week (scheduled house handover at the end of January, thus just missing the VAT reduction as well). 90% of the house price has already been paid; only the final invoice, likely arriving in the next few weeks, remains open.

At the end of November, the exterior plaster was applied. At that time and in the days following, the outside temperature did not exceed 5 degrees, with nighttime temperatures occasionally below freezing. According to the plaster manufacturer (Alsecco), the silicate plaster used may only be applied up to 5 degrees Celsius outside temperature and must remain above 5 degrees consistently in the days after. If this is not the case, the plaster cannot properly cure, which can lead to damage regarding strength and durability.

One day before the plaster work began, we submitted an informal notice of concern to the general contractor and the construction coordinator regarding the weather forecast. In response, the subcontractor stated that there was no reason to worry and that he was even offering a one-year extended warranty on his own initiative.

The plastering was carried out, with the result that the exterior plaster was still soft even after a week. In some places, it has "slid down," especially on window sills. See pictures for details.

The subcontractor who applied the exterior plaster also recently installed the window sills—but only after the external thermal insulation composite system (ETICS) and facade reinforcement were applied—and they installed them crooked and uneven. In some cases, the window sills also seem to be too short. On average, they protrude only about 2-3 cm. Some are also uneven, for example, one side 1.5 cm, the other side 3 cm. The underside drip groove is often flush with the facade. Drinking took place during the installation of the window sills, as evidenced by several (approximately middle double-digit) "short drinks" found scattered near the scaffolding. It was also "nice" that our sometimes 3 m long window sills were simply cut with an angle grinder because, as stated, they would not otherwise have fit into the car. It was forgotten that the joint then needed to be sealed.

The window sills also show no visible sealing. According to professional associations, there should be two sealing levels on window sills with ETICS. I see none. I also find it odd that the window sills were cut into the ETICS. The unnecessarily large gaps created there were either not filled at all or only with silicone or similar, which after more than four weeks is still not cured and is soft.

Water continually collects on the edges of the window sills, running down the facade, further soaking the plaster, and in some places freezing or freezing into the plaster. Where could this water be coming from? Inside, the screed drying process is still ongoing with corresponding heat. Could this be an indication of leaks around the windows? The interior moisture is consistently removed using three construction dryers (currently below 40% humidity). The suspicion of a leak around the windows arises because I found significant residual moisture along with slight bulging of the interior plaster at the worst-affected window corner inside. Elsewhere, the interior plaster is superficially dry.

The base of the house was also only half-heartedly delivered by the same subcontractor. A very thinly scratched reinforcement plaster can never be the sealing plaster against moisture as agreed in the construction services description because it is simply too thin and, as the pictures show, always damp (without rain!).

Outlook:

What happens next? The defects have been reported, documented with photos, and recorded. Should one still accept the handover conditionally with such defects, or refuse acceptance altogether? We would like to move in at the end of February, as my wife has her follow-up treatment after chemotherapy starting in March and does not need moving stress afterward, which would negate any recovery. The possible double burden is also not without consequence.

The plaster is visibly ruined and in reality crumbly, patchy, and simply poorly done. In our opinion, it must be completely removed and redone. The window sills must also be taken out and reinstalled, as they are too short and in some cases unnecessarily cut with an angle grinder. Our concern is especially the sealing and possible damage to the ETICS. Who knows what it will be like in a few years.

Next week, at our own expense, we will bring in a publicly appointed expert for the painting trade to clarify the severity of the damage and necessary repairs. From the general contractor and our site manager, based on experience, we expect little to nothing. We want to remain firm and not agree to any repair work or credit notes. For now, we only see the solution as "everything from scratch." That would be really expensive and particularly interesting regarding payment of the final installment.

We have only received a 5% completion bond from the general contractor, which would probably not be sufficient for a complete re-execution of the defect (and according to the contract text, may only be retained after the house handover for serious defects). However, referring to this bond, he has already suggested that under all circumstances he will insist on 100% payment by us upon acceptance, as we have this bond from him as security and it could be increased or extended.

Hints, comments, ideas, suggestions ... all welcome. I just had to "vent." Sometimes you really feel helpless and lost as a building owner.