Stephan—

2021-02-11 23:10:31

- #1

Hello professionals,

I would like to gather some diverse opinions on the following project (see title).

I have absorbed various forums and sites on the mentioned topics and envision the following solution.

Controlled residential ventilation: (self-installation of flexible ducts, devices, distributors, etc., except commissioning and balancing)

- Flexible ducts (round) 75mm OD with 61 or 63mm ID

- for ground floor on raw concrete floor in insulation under underfloor heating

- for upper floor over precast ceiling, cast in-situ concrete (incl. valves) and have approved by the structural engineer

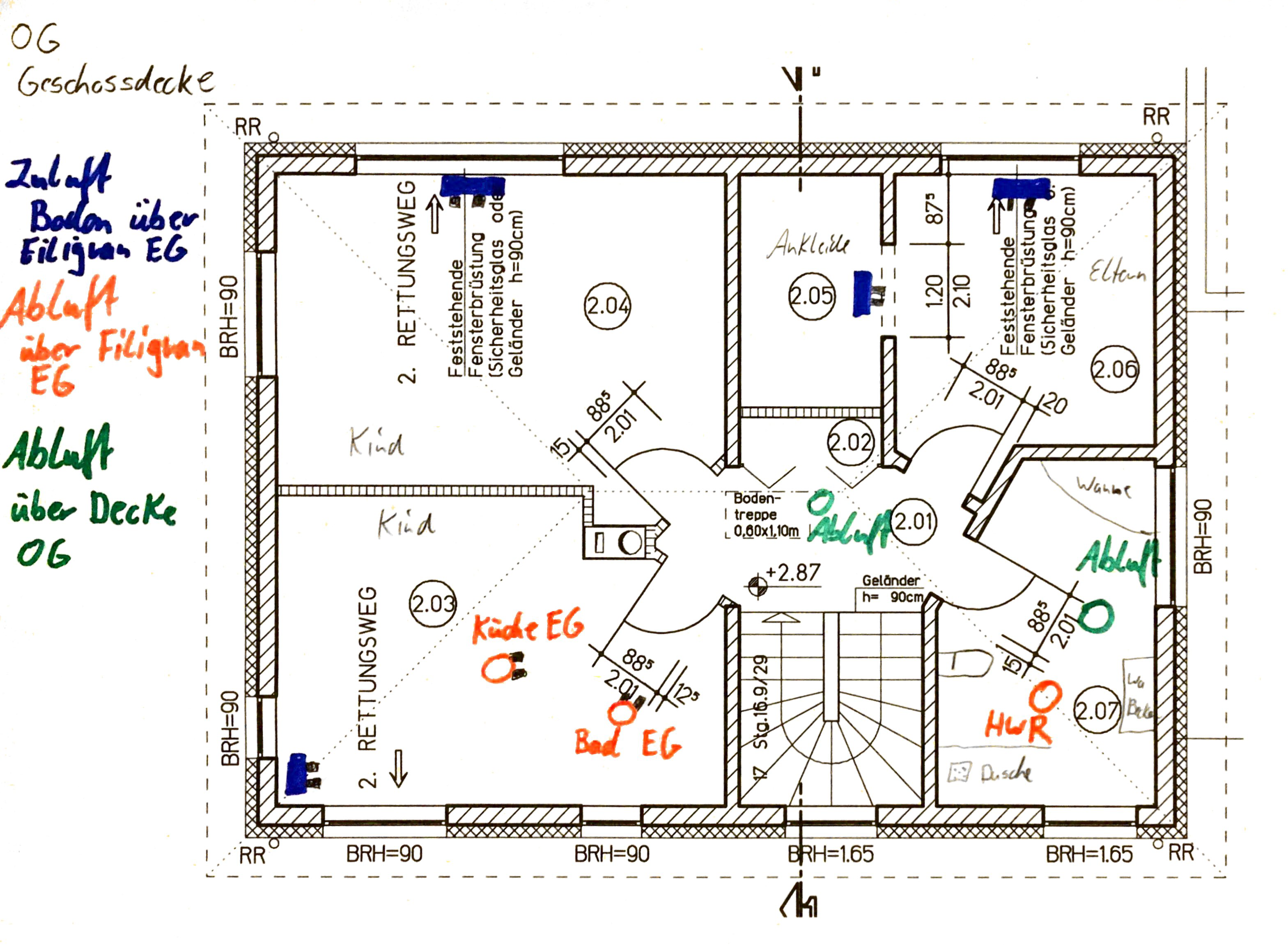

- exhaust air from bathroom and corridor upper floor via attic (cold roof)

- all supply air valves via floor inlets (incl. 2 connections for flexible duct)

- all exhaust air valves via ceiling valves 125mm (incl. 2 connections for flexible duct)

Supply air for controlled residential ventilation 200mm through floor slab KG from "outside" via air well (just search engines and get inspired)

Exhaust air 200mm through floor slab to outside into a shaft (with slope for condensate and permeable) and at ground level with grid grate

Provide grease extraction under floor slab using 150mm KG and also "ventilate" it into the above-mentioned shaft

Supply chimney with 200mm KG under floor slab with fresh air and connect condensate drain to sewage system

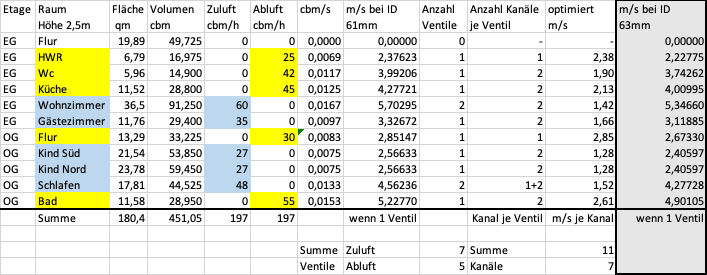

I have calculated the controlled residential ventilation with various tools (Helios, Wolf, Selfio (had it calculated), Vallox, Maico) and come up with the following idea (pressure drop not considered):

In rooms at rest, e.g. bedrooms max. 2m/s, in the rest max. 3m/s

Motto: Better to install one more pipe than have the "noise" later

PS:

Proper supply air, when controlled residential ventilation is stopped because grease extraction is running, must also be accommodated.

I am thinking about installing a Maico and saving enthalpy & EWT or brine heat exchanger through air wells.

I look forward to lively participation, positive or negative.

Good idea or "not hearing the shot"? :)

I would like to gather some diverse opinions on the following project (see title).

I have absorbed various forums and sites on the mentioned topics and envision the following solution.

Controlled residential ventilation: (self-installation of flexible ducts, devices, distributors, etc., except commissioning and balancing)

- Flexible ducts (round) 75mm OD with 61 or 63mm ID

- for ground floor on raw concrete floor in insulation under underfloor heating

- for upper floor over precast ceiling, cast in-situ concrete (incl. valves) and have approved by the structural engineer

- exhaust air from bathroom and corridor upper floor via attic (cold roof)

- all supply air valves via floor inlets (incl. 2 connections for flexible duct)

- all exhaust air valves via ceiling valves 125mm (incl. 2 connections for flexible duct)

Supply air for controlled residential ventilation 200mm through floor slab KG from "outside" via air well (just search engines and get inspired)

Exhaust air 200mm through floor slab to outside into a shaft (with slope for condensate and permeable) and at ground level with grid grate

Provide grease extraction under floor slab using 150mm KG and also "ventilate" it into the above-mentioned shaft

Supply chimney with 200mm KG under floor slab with fresh air and connect condensate drain to sewage system

I have calculated the controlled residential ventilation with various tools (Helios, Wolf, Selfio (had it calculated), Vallox, Maico) and come up with the following idea (pressure drop not considered):

In rooms at rest, e.g. bedrooms max. 2m/s, in the rest max. 3m/s

Motto: Better to install one more pipe than have the "noise" later

PS:

Proper supply air, when controlled residential ventilation is stopped because grease extraction is running, must also be accommodated.

I am thinking about installing a Maico and saving enthalpy & EWT or brine heat exchanger through air wells.

I look forward to lively participation, positive or negative.

Good idea or "not hearing the shot"? :)