Reini1234

2019-02-11 10:33:35

- #1

I just came from my construction site and have the feeling that the execution of my controlled residential ventilation is going completely in the wrong direction.

Initial situation:

Actually, I wanted to subcontract the ventilation system trade entirely without dealing with it much. At the sanitation guy, a Wolf CWL 400 with 50x140cm flat duct was ordered. The company then installed the valves for the basement rooms in the filigree ceiling during the basement construction and left a few meters of pipe standing up. These were then supposed to be continued into the installation level of the timber frame house up to the attic.

Recently, I was offered to install the remaining pipes myself on a time and material basis, which we accepted.

The device is hanging in the attic on the gable wall above the bathroom. The two air distributors are directly in front of it. From there, all supply and exhaust air valves in the house are controlled. All flat ducts are connected so far, the supply and outdoor air are not connected yet.

The installer came by a few times, briefly checked if everything fit, and was done. I increasingly had the feeling that everything was done roughly and I was still surprised that there were apparently no guidelines or anything similar. Recently, I received the ventilation concept, which I have now studied more closely.

It mentions a minimum and maximum duct length of 5-15m. I complied with the 5m, but the maximum length is mercilessly exceeded for the basement rooms:

Basement room exhaust air 12.50m

Basement room supply air 20.00m

Basement utility room exhaust air 17.00m

Basement corridor supply air 15.80m

Basement supply exhaust air 13.30m

Basement WC exhaust air 8.50m

What exactly does a pipe that is too long cause? Can the ventilator no longer handle it then? I might pull the long 20m duct out again and save a few meters by routing it along the floor, but I will not reach the 15m limit. There are already 4 bends here alone.

Does it make sense to swap the much shorter exhaust air with the supply air?

Other things I noticed:

-We were not provided with fixed bends and bent everything ourselves. Especially the 90-degree transition from floor to wall looks like in the pictures. Due to the kink, the pipe is somewhat compressed; what consequences can this cause?

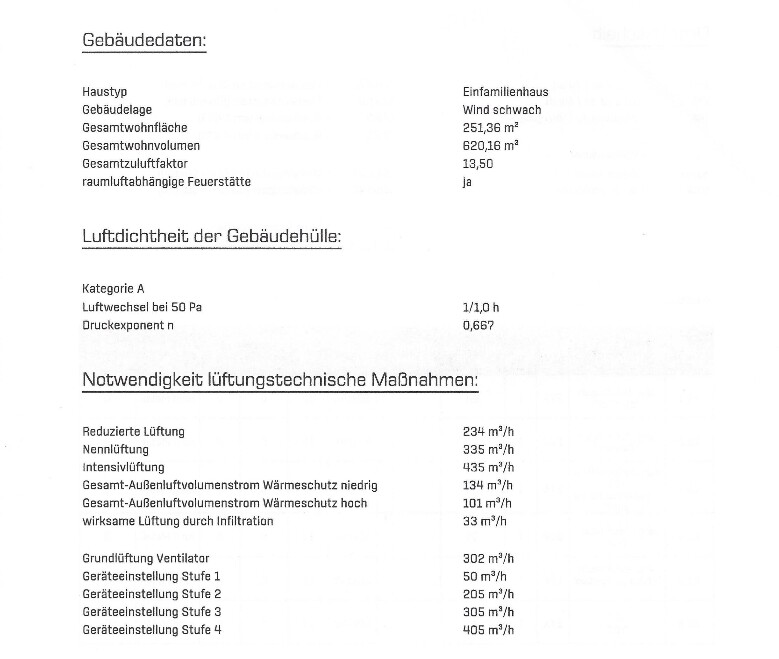

Attached is also my ventilation concept

Initial situation:

Actually, I wanted to subcontract the ventilation system trade entirely without dealing with it much. At the sanitation guy, a Wolf CWL 400 with 50x140cm flat duct was ordered. The company then installed the valves for the basement rooms in the filigree ceiling during the basement construction and left a few meters of pipe standing up. These were then supposed to be continued into the installation level of the timber frame house up to the attic.

Recently, I was offered to install the remaining pipes myself on a time and material basis, which we accepted.

The device is hanging in the attic on the gable wall above the bathroom. The two air distributors are directly in front of it. From there, all supply and exhaust air valves in the house are controlled. All flat ducts are connected so far, the supply and outdoor air are not connected yet.

The installer came by a few times, briefly checked if everything fit, and was done. I increasingly had the feeling that everything was done roughly and I was still surprised that there were apparently no guidelines or anything similar. Recently, I received the ventilation concept, which I have now studied more closely.

It mentions a minimum and maximum duct length of 5-15m. I complied with the 5m, but the maximum length is mercilessly exceeded for the basement rooms:

Basement room exhaust air 12.50m

Basement room supply air 20.00m

Basement utility room exhaust air 17.00m

Basement corridor supply air 15.80m

Basement supply exhaust air 13.30m

Basement WC exhaust air 8.50m

What exactly does a pipe that is too long cause? Can the ventilator no longer handle it then? I might pull the long 20m duct out again and save a few meters by routing it along the floor, but I will not reach the 15m limit. There are already 4 bends here alone.

Does it make sense to swap the much shorter exhaust air with the supply air?

Other things I noticed:

-We were not provided with fixed bends and bent everything ourselves. Especially the 90-degree transition from floor to wall looks like in the pictures. Due to the kink, the pipe is somewhat compressed; what consequences can this cause?

Attached is also my ventilation concept