JumpY

2025-09-28 12:20:07

- #1

Hello everyone,

we have a detached conservatory and would like to renew the floor there and are considering the correct execution regarding insulation.

Current situation:

Overall floor construction:

Now the question arises which type of insulation is best suited to make the floor warmer. We can build up a maximum of 50mm higher, i.e. including the floor covering about 60mm are available from the top edge of the OSB. (Higher is not possible, that is the upper edge of the glass profile of the conservatory)

The final floor covering is not yet fixed, we are happy to receive recommendations for this – we can imagine bringing the adjacent living room to the same height in one go and using the floor there as well.

Does it make sense to open the entire cladding etc. from below and change the insulation there or is the effect probably rather small? (my assessment) I can imagine laying a 40mm EPS 035 insulation on the OSB boards and the new floor on top of that. Also conceivable would be to integrate underfloor heating if it can be sensibly integrated into the 60mm build-up including covering. This of course would provide a larger heating surface in addition to the radiators and could counteract the cold floor.

It might also be possible to make changes from above and below, although removing the entire cladding from below is relatively much effort.

I would be very happy to receive advice or tips.

Best regards

we have a detached conservatory and would like to renew the floor there and are considering the correct execution regarding insulation.

Current situation:

[*]The support structure consists of a steel beam construction completely lined with wood

[*]The current floor covering is a click linoleum with a thickness of 11mm

[*]The floor is very cold and not walkable without shoes except in summer. Even with shoes, after some time you can clearly feel cold coming from below

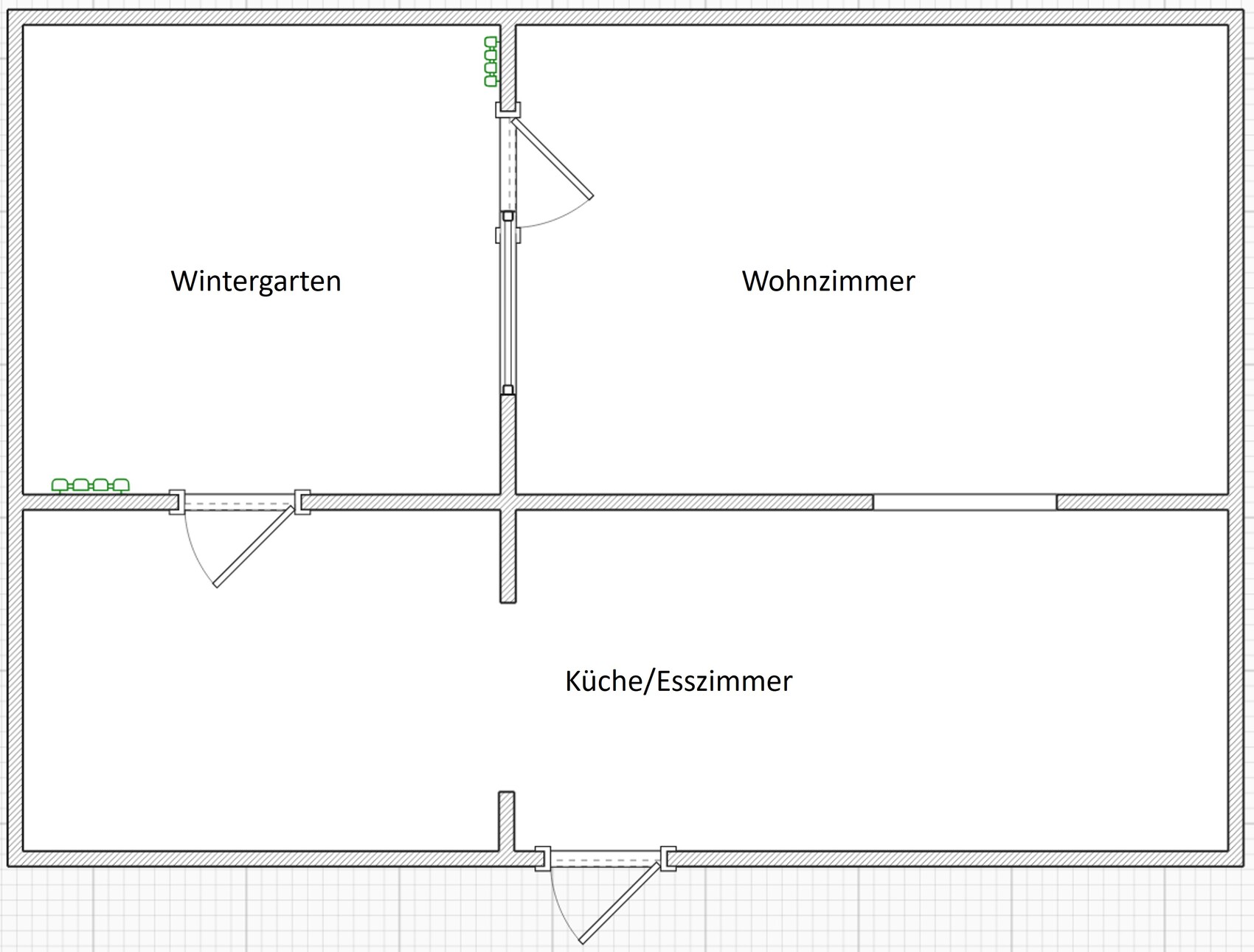

[*]The conservatory is connected on two sides to the building/brick wall and has two large doors leading into the living area (kitchen + living room)

[*]Currently, the conservatory is heated with two vertical tube radiators (relatively flat)

Overall floor construction:

[*]I have visualized the entire floor construction as it is today

[*]The glass wool lies in the steel beams between the two flanges, but I could not represent this better

[*]The construction can be seen in the photos

Now the question arises which type of insulation is best suited to make the floor warmer. We can build up a maximum of 50mm higher, i.e. including the floor covering about 60mm are available from the top edge of the OSB. (Higher is not possible, that is the upper edge of the glass profile of the conservatory)

The final floor covering is not yet fixed, we are happy to receive recommendations for this – we can imagine bringing the adjacent living room to the same height in one go and using the floor there as well.

Does it make sense to open the entire cladding etc. from below and change the insulation there or is the effect probably rather small? (my assessment) I can imagine laying a 40mm EPS 035 insulation on the OSB boards and the new floor on top of that. Also conceivable would be to integrate underfloor heating if it can be sensibly integrated into the 60mm build-up including covering. This of course would provide a larger heating surface in addition to the radiators and could counteract the cold floor.

It might also be possible to make changes from above and below, although removing the entire cladding from below is relatively much effort.

I would be very happy to receive advice or tips.

Best regards