phlipzner

2010-03-17 15:32:45

- #1

hello,

our bathroom was renovated a few years ago by an acquaintance.

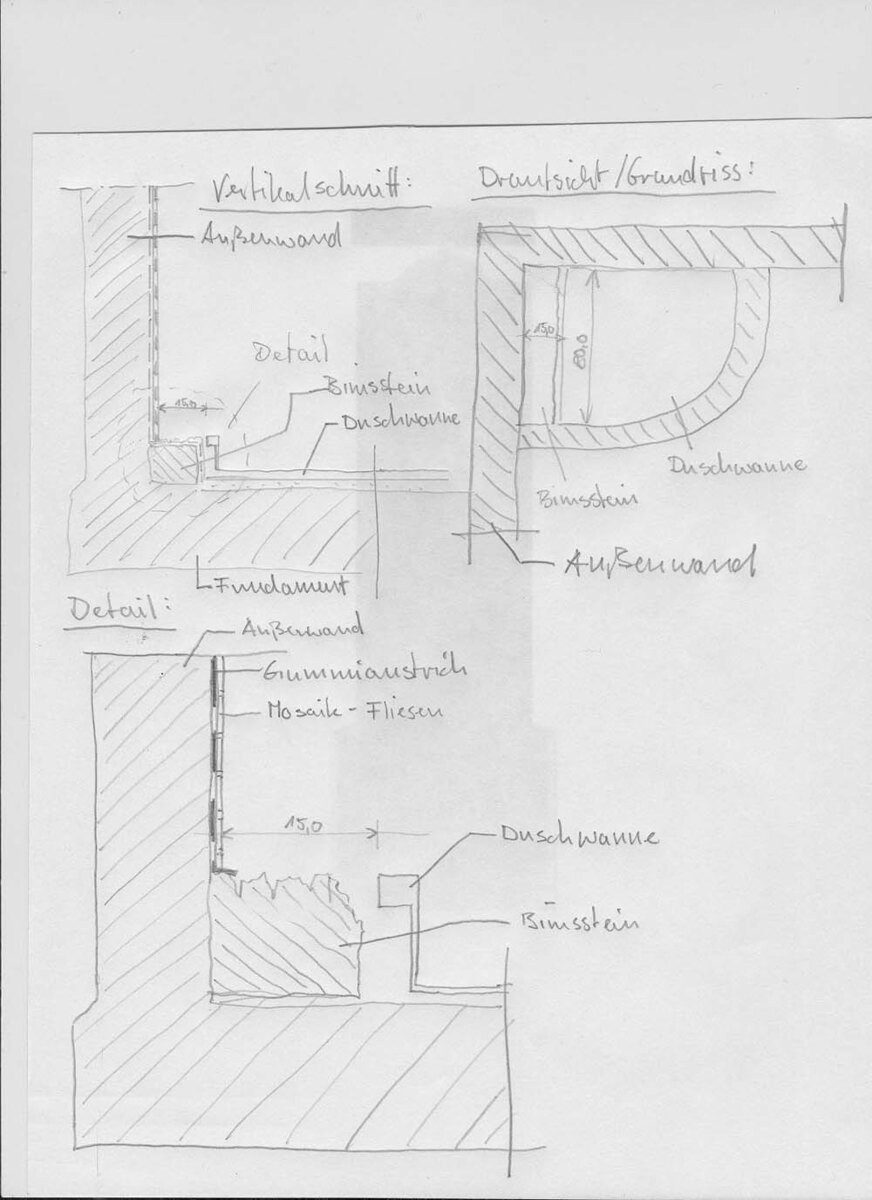

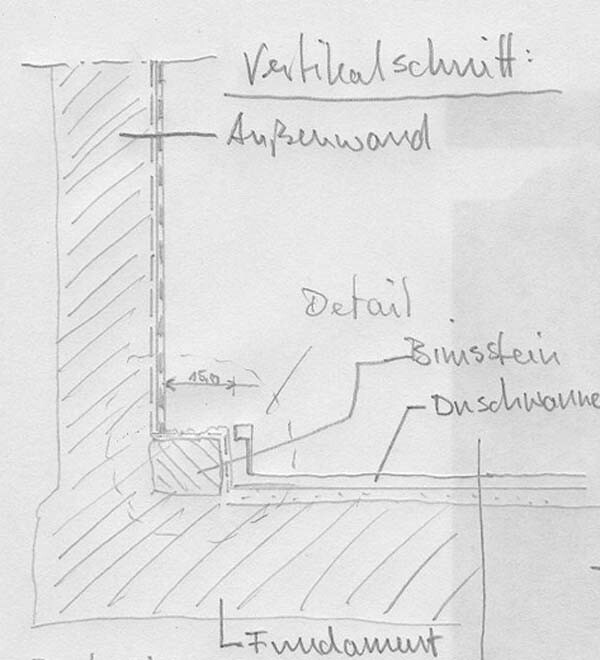

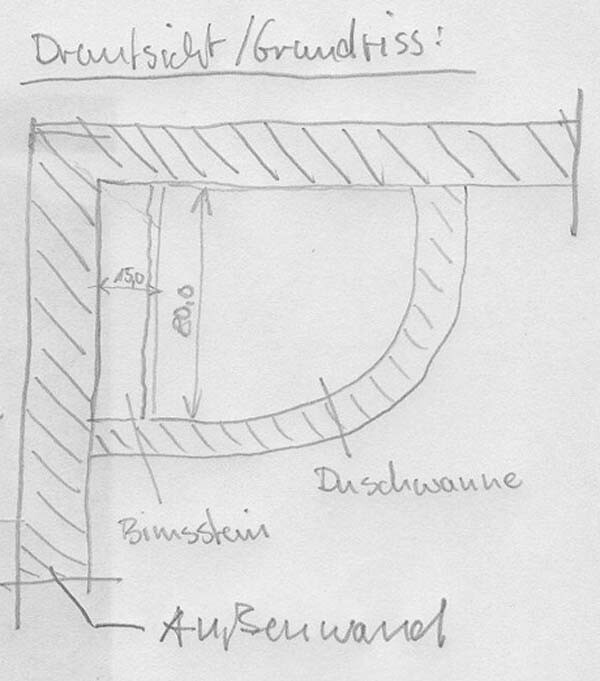

We have a masonry shower enclosure with a plastic shower tray.

Now we had water ingress at the silicone joint between the pumice stone

and the shower tray (see sketch). The pumice stone was previously tiled,

the sketch shows the status quo.

The cause of the leak is probably that the joint width was sometimes

only 2mm. In the meantime, I have scraped out all the joints,

removed the tiles and the rubber coating from the horizontal pumice stone,

so that it can dry again.

How do I make the shower watertight permanently now?

My idea was to double up the pumice stone, apply a new rubber coating,

tile again, so that the joint from pumice stone to shower tray forms a

90-degree corner, which is probably easier to seal than if the surfaces

are at 180 degrees to each other as before, is that correct?

But if I double up the pumice, I will also get more joints all around,

where the pumice abuts the walls end-on, all of which I have to seal.

Or should I simply tear out the old tiles completely,

double up the pumice, apply new rubber coating completely, and retile?

I am totally annoyed but want it to be permanently watertight this time,

so I am grateful for any tip and hope what I wrote is understandable!

Best regards : )

our bathroom was renovated a few years ago by an acquaintance.

We have a masonry shower enclosure with a plastic shower tray.

Now we had water ingress at the silicone joint between the pumice stone

and the shower tray (see sketch). The pumice stone was previously tiled,

the sketch shows the status quo.

The cause of the leak is probably that the joint width was sometimes

only 2mm. In the meantime, I have scraped out all the joints,

removed the tiles and the rubber coating from the horizontal pumice stone,

so that it can dry again.

How do I make the shower watertight permanently now?

My idea was to double up the pumice stone, apply a new rubber coating,

tile again, so that the joint from pumice stone to shower tray forms a

90-degree corner, which is probably easier to seal than if the surfaces

are at 180 degrees to each other as before, is that correct?

But if I double up the pumice, I will also get more joints all around,

where the pumice abuts the walls end-on, all of which I have to seal.

Or should I simply tear out the old tiles completely,

double up the pumice, apply new rubber coating completely, and retile?

I am totally annoyed but want it to be permanently watertight this time,

so I am grateful for any tip and hope what I wrote is understandable!

Best regards : )