alive&kicking

2021-09-25 00:35:34

- #1

Hello everyone,

I’m currently in a jam and running out of time that I actually don’t have right now. (I have to specify the sizes of the core drillings, but the execution is not settled, as it has now turned out (Radon).)

Normally, I read in forums before posting a question... I did, but certainly not enough.

We have had a controlled residential ventilation system (ComfoAir Q350 TR enthalpy) planned, we wanted to do the installation ourselves back then, well, now I would have done it differently and had it built.

The question that arises below is how do I drain the condensate that occurs in the external pipes?

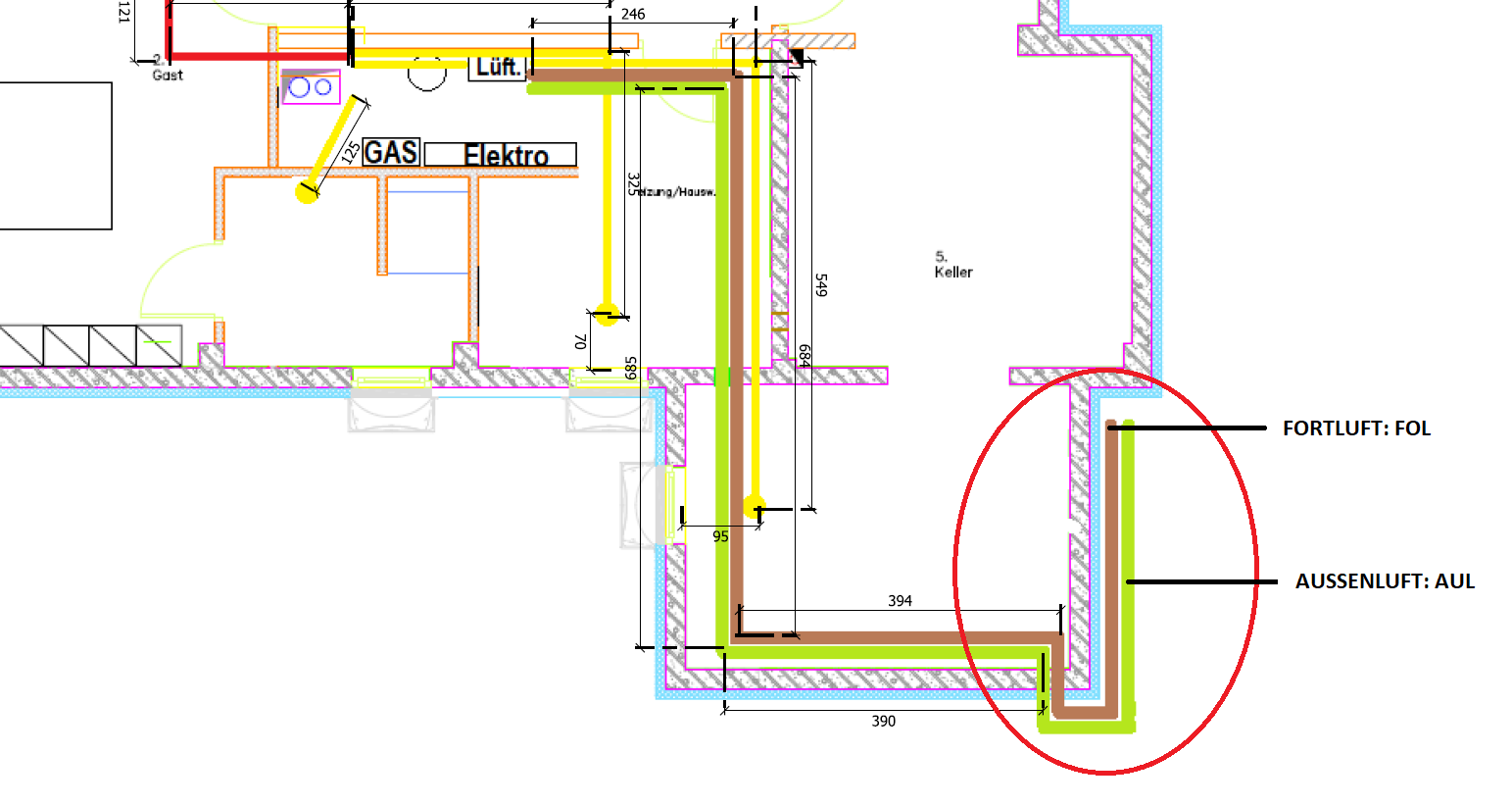

The building situation (Upper Bavaria) is as follows (also visible in the picture below). Ventilation system in the basement (warm), pipes to the outside wall in ComfoPipe and spiral seam pipe, Doyma seal. Outside there are KG pipes DN200 (uninsulated), which are to be used as ventilation pipes, they lie at about 50-60 cm depth, for about 2-3 meters, then passing under an already existing garage slab and then routed over the carport roof. I know the line length is enormous.

Since the topic of Radon came up again, not just now, I rejected the proposal of condensate drainage in the ground area and am now looking for another option.

My current idea is this, but I am extremely uncertain because I have not read much.

FOL (exhaust air):

from the ventilation unit uninsulated in spiral seam pipe to the outside wall, transition to KG DN 160 still inside, Doyma seal, transition to KG DN 200 with slope, then somewhere a T-piece and 20 cm pipe downwards for drainage (with grid/fleece?), further with an incline in KG DN 200, insulate KG pipe above the garage slab, then stainless steel ventilation bend DN 160 (?)

AUL (fresh air):

intake bend made of stainless steel DN 160 (?), transition to KG DN 200 uninsulated, horizontally under the garage slab with slope to the house wall, transition to KG DN 160, connection to ComfoPipe DN 160, Doyma seal, element with condensate drain (for now) into a container, further in ComfoPipe to the ventilation unit.

Cautiously asked, is this a technically sensible variant?

Based on my limited knowledge, that more condensate forms in the FOL than in the AUL????

(here in parentheses, of course there would be a possibility to blow the FOL out through a basement shaft in the building services room, but there is our garden terrace, don’t know if that bothers. However, in summer we actually want to run the controlled ventilation low because we will have everything open.)

I would be very happy about answers and/or other suggestions.

Attachment:

Building situation

I’m currently in a jam and running out of time that I actually don’t have right now. (I have to specify the sizes of the core drillings, but the execution is not settled, as it has now turned out (Radon).)

Normally, I read in forums before posting a question... I did, but certainly not enough.

We have had a controlled residential ventilation system (ComfoAir Q350 TR enthalpy) planned, we wanted to do the installation ourselves back then, well, now I would have done it differently and had it built.

The question that arises below is how do I drain the condensate that occurs in the external pipes?

The building situation (Upper Bavaria) is as follows (also visible in the picture below). Ventilation system in the basement (warm), pipes to the outside wall in ComfoPipe and spiral seam pipe, Doyma seal. Outside there are KG pipes DN200 (uninsulated), which are to be used as ventilation pipes, they lie at about 50-60 cm depth, for about 2-3 meters, then passing under an already existing garage slab and then routed over the carport roof. I know the line length is enormous.

Since the topic of Radon came up again, not just now, I rejected the proposal of condensate drainage in the ground area and am now looking for another option.

My current idea is this, but I am extremely uncertain because I have not read much.

FOL (exhaust air):

from the ventilation unit uninsulated in spiral seam pipe to the outside wall, transition to KG DN 160 still inside, Doyma seal, transition to KG DN 200 with slope, then somewhere a T-piece and 20 cm pipe downwards for drainage (with grid/fleece?), further with an incline in KG DN 200, insulate KG pipe above the garage slab, then stainless steel ventilation bend DN 160 (?)

AUL (fresh air):

intake bend made of stainless steel DN 160 (?), transition to KG DN 200 uninsulated, horizontally under the garage slab with slope to the house wall, transition to KG DN 160, connection to ComfoPipe DN 160, Doyma seal, element with condensate drain (for now) into a container, further in ComfoPipe to the ventilation unit.

Cautiously asked, is this a technically sensible variant?

Based on my limited knowledge, that more condensate forms in the FOL than in the AUL????

(here in parentheses, of course there would be a possibility to blow the FOL out through a basement shaft in the building services room, but there is our garden terrace, don’t know if that bothers. However, in summer we actually want to run the controlled ventilation low because we will have everything open.)

I would be very happy about answers and/or other suggestions.

Attachment:

Building situation